Seven Million is a high-end ready-to-wear manufacturing workshop specialized in manual

textile skills such as weaving, embroidery and screen printing and, more recently, block

printing. The workshop is based in the Bengal region, 100 km from Kolkata.

Seven Million is the number of artisans recorded by the Indian government at the time we set

up our workshop. The name symbolises a landmark.For nearly 10 years, we have been striving

to regain potential of what we believe is precious in our land: manual trades and the unique

and ancestral heritage that they guard.

Seven Million combines industrial processes with entirely artisanal crafts, making it a

completely unique organization.

Workshop

Our current workshop covers 4500m2. Dyers for Yarn and fabrics, Hand screen printing and hand block printing, Hand embroidery, Pattern making, cutting, stitching, quality controle, sales and administrative team are working under one building which conclude to nearly 180 people intotal. Together, we produce around 100,000 pieces annually.

Our expansion had to be accompanied by a new workshop, a workshop designed entirely for the needs of Seven Million. With the new unit we can produce around 500000 pcs annually. So, near Bardhaman, 80 kilometers from Kolkata airport, the construction of the workshop we dreamed of at the beginning is now commenced its production from September 2023. On almost two hectares, divided into two separate sites 500 meters apart, we have created our ideal space. Close to the transport routes, we built a four-story building dedicated to our production. While the weaver will continue to work from their village, in our collaboration we will carry out all subsequent steps such as printing, embroidery, and garment making here.

A unique workplace where the modern machines and textile engineers are at the service of skilled rich artisans who are good at hand weaving and hand embroidery but not in textile engineering. So in 7million we could find a perfect combination inbetween this two and create a unique product and sustainable production process which can compete to any made in.

Studio

A little further stands a building designed as a creative studio, where our teams will provide their expertise to best support our customers in exploring the many technical and creative possibilities offered by Seven Million.

Moreover, accomodation near the sight is offered to all our customers. Finally, our nez sight includes a pond, a field cultivated according to organic methods and a residence welcoming our employees who wish to stay near their work.

This ambitious project aims to provide all creatives with the perfect playground. From the idea that germinates in the mind to its realization, everything will take place in one spot, in the heart of the Bengal rice fields.

Our architect Laurent Fournier did an wonderfull creative work by using 50-60 years old chettinad wooden pillars from south of India and 100 years old wooden doors and wondows from Kolkata Jamindar house. A perfect combination of a recycled sustainable atelier in the service of our creative brand designers.

know how

A little further stands a building designed as a creative studio, where our teams will provide their expertise to best support our customers in exploring the many technical and creative possibilities offered by Seven Million.

Their vision from the start was to internalize production with the objectives of:

And so the Atelier Seven Million was born. Since then, it has produced for the brand of its founders as well as for a selection of brands that share the love of handmade textiles and the values of the workshop. Today, we wish to put our expertise at the service of a selection of other brands with the aim of extending the unique model we have created to more artisans. Ultimately, we hope to create a foundation for the training of younger generations in these know-hows.

Printing and Dyeing

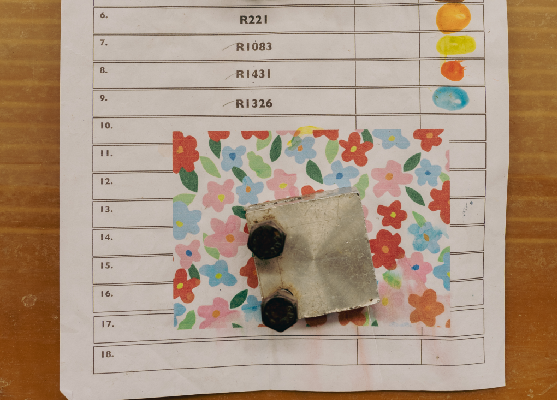

We have developed all the industrial tools to print your patterns on a flat frame. This process is also entirely manual. We can print your drawings using up to 20 colors. Our team can develop your custom color range from fabric samples or a Pantone TPG reference. We print silk, wool, cotton, linen or blends and we only work with natural fibers. Our graphics designer Sayan can put your drawings into perspective and adapt your files for screen printing.

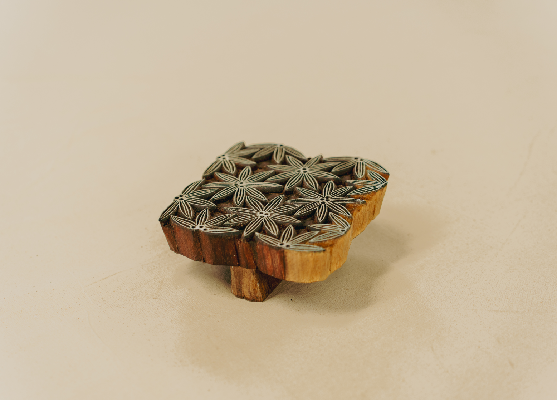

Additionally, we recently developed block printing. The craft of block printing has gradually disappeared in Bengal over the last few decades; however, it is still widely practiced in India in the Jaipur region. We are committed to reviving this practice in the region. We are working to develop this exclusive craft further and have reserved printing tables for its practice in Bengal.

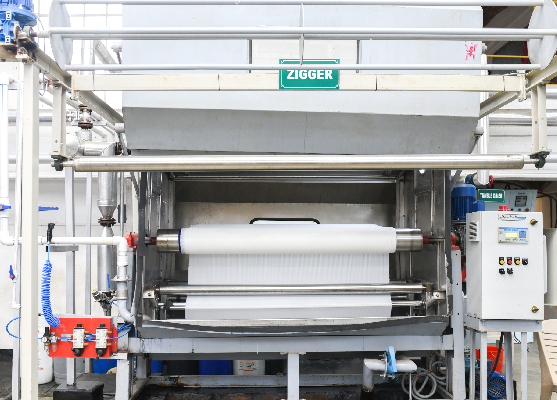

All dyeing is done at the workshop. We have 4 dyeing machines with a capacity of 300 kg / day, the equivalent of 3000 hand-woven fabrics. We practice yarn or fabric dyeing.

Hand weaving

The fame of Bengali fabrics is largely due to the fabulous fineness of its cottons. Khadi cotton, silk cotton, and muslin cotton are the weaves in which our weavers excel. Jamdani weaving is also an exceptional weaving technique particularly renowned in Bengal and which we master. As part of the developmentof Seven Million’s activities, we have expanded our network of collaborators. We procure handmade fabrics which are made through fully manual and traditional wooden looms.

Hand weaving is an entirely artisanal technique for which we have developed a unique circuit combining industrial and artisanal processes. The threads are first dyed in our workshop (in compliance with the Reach standard). This allows us to customize all weaves to the colors of your season. Textile engineers and artisans work closely together. The threads are then woven accoring to your designs and create unique and bespoke weaves.

Hand embroidery

Hand embroidery is closely linked to the Seven Million workshop since its foundation. The embroiderers of the region are known throughout India for their excellence in technique and creativity. We have 15 embroiderers in our workshop, but we are able to expand to 200 embroiderers in case of high production. We create the embroideries in aari or needlework.More than any other technique, embroidery allows for the creation of unique and bespoke designs. We can develop all types of embroidery with a variety of unique stitches and with all types of materials. More specifically, we also work on the exceptional technique of Kantha which is particularly known in the Bengal region. It allows for the creation of quilted and patchwork effects.

10 embroiders work in our workshop for production.

Cutting, stitching, Finishing

Quality controle

We have 800 sq mt space in the building which is dedicated for Cutting ( Single panel cutting for hand embroidery pcs and as well layer cutting ), total 54 sewing machine strength. We have the expertise to stitch small lots and single pc stitching for high end luxury sector and as well chain system assembling for bigger volume of production. We have 800 sq mt space dedicated for hand finishing, roll hemming, hand stitching. In the same space we give a special care for 1st layer quality control before ironing and then a final quality control before it gets packed for dispatch.

OUR STORY

The Atelier Seven Million originated from a couple. One is Bengali Indian and the other is French. In 2006, Bapan and Lucie met at the School of Decorative Arts in Paris, where they studied textile design. They fell in love and began a long adventure of exploration, exchange and creation around textile know-how and between their two cultures. Their first trip together to India in 2009 gave them a new breath of life. They saw the local industry and came to a clear conclusion: the knowhow was unique but very disorganized. Some dyeing steps, in particular, were carried out without any respect for standards or environmental consciousness. Artisans and artists were not valued as they should have been, resulting in disinterest from younger generations for these manual trades. Without being imminent or even really felt, the disappearance of these know-hows seemed inevitable for several decades.

OUR team

Seven Million stands out by internalizing almost the entire production chain. Operating without intermediaries is a significant advantage; it allows us to better manage costs as well as having full control over quality. This however requires competent teams in various fields. The team consists of 182 employees.

08

Key Management

54

Production Pole

15

Embroidery Pole

34

Printing Pole

18

Finishing Pole

13

Quality Control Pole

09

Collection Pole

31

Admin, Store & Others

Sucharita

Manager Print&Dye

Bibhas

Manager dye

Bidhan

Store manager

Borun

Stitching line supervisor Name

Jalil

Floor supervisor

Mohitosh

Senior QC

Sandip

Seniro production manager

Sanjoy

Senior Designer

OUR COMMITMENT

ENVIRONMENTAL RESPONSABILITY

In line with what we have been applying since our creation, the entire project has been designed first and foremost with the ambition of being as respectful of the environment as possible. To do this, we called on French architect Laurent Fournier, practicing in Kolkata and its region for more than 30 years. More than bio-climatic architecture (and this is the reason why we solicited him), he is a specialist in vernacular architecture of Bengal. Thus, his first concern was to reduce the recourse of artificial light and air conditioning system. He did so by using techniques that have been in use for a long time by the populations of the region.

The orientation of the buildings as well as a work of natural ventilation have been a central point of his reflection, as well as a fidelity to techniques and materials that have demonstrated their effectiveness in thetropical climate where we operate.

The use of brick, particularly for the construction of domes, which are the visual identity of the project, creates a unique space.

This is complemented by a range of installations aimed at optimizing our energy balance: Underground water tanks with a capacity of 200,000 liters were built, collecting during the monsoon season water that will be used for the rest of the year. 50% of daily water consumption for production will be covered by rainwater collected.

The site has its own effluent treatment system (ETP), with a long-term objective of reaching zero liquid discharge (ZLD plan). To do this, we are working with a company based in Pune spe cializing in ecological treatment of water through natural filtra tion. A combination of natural plants and bacteria are used to absorb pollutants. This process has the advantage of not requi ring any electricity. In addition to a closed and odorless circuit that will provide us with clean, reusable water, it is also a beautiful vegetation that will be added to the decor.

Solar panels will be installed to provide 50% of the electricity.

To help us improve and maintain a high level of exigency on environmental issues, a «green consultant» also joined our teams.

We are training our team in natural Dye.

SOCIAL RESPONSABILITY

In addition to our environmental responsibility, our social responsibility is, and remains, a primary issue. Since the creation of the company, we put in place all the social protections for our team: the coverage of medical expenses for our employees and their families and the contribution to a retirement fund.

The salaries of our team are indexed to the rate set each year by the Indian government but we are always between 15 and 30% above these recommendations. Finally, salaries are revalued annually in relation to the increase in the standard of living.

In order to promote training, French language courses have been offered to the management team for a few months by a VIE.

In partnership with a local association, we wish to develop links with the adjacent village of the new workshop site. The inhabitants of the village struggle with many issues, the main ones being the difficulty of accessing the education and health system and the lack of employment opportunities. Our presence will offer new opportunities to dozens of people. Since women in the village struggle to find a job more than men, we believe that the possibility of being trained and working close to their homes will be beneficial to their entire family. Finally, we will apply for the SA8000 certification as soon as the new site is operational.

Bio-Climatic Building

contact us

Factory Address

Jajanpur, On NH-2Jaugram Gram panchayat

Purba Bardhaman 713166

West Bengal, India

Bapan Dutta

CEO of 7Million

bapan@sevenmillion.in

India +919073353480

France +33670051742

Solenne Gilles

Executive development manager

France

solenne@sevenmillion.in

Tapas Modi

Senior merchandiser

India

Sr.adv2@sevenmillion.in

Whatsapp/ call - +919046155054